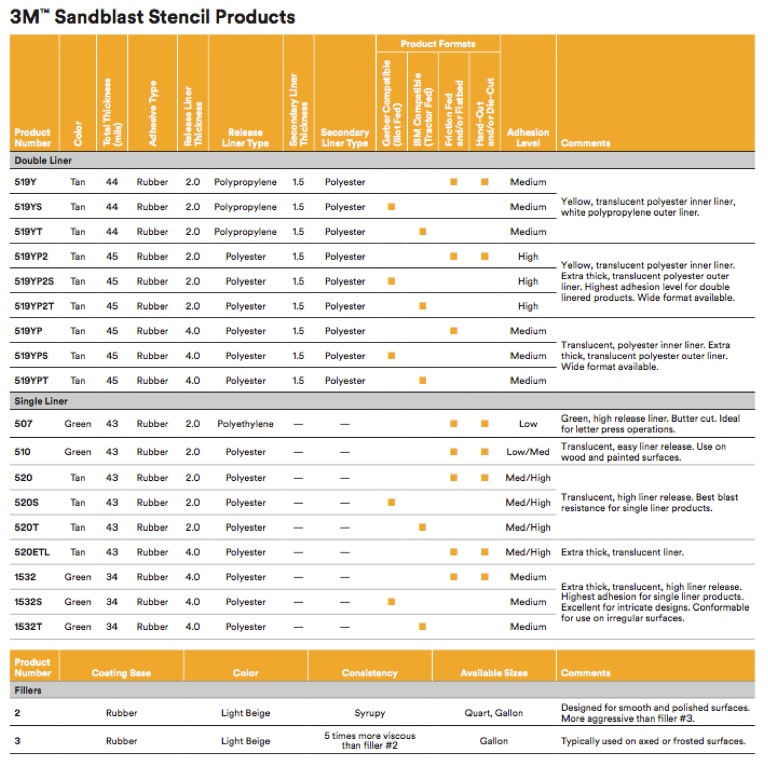

3M NO LONGER manufactures stencil rubber for stone. However we’re temporarily keeping this page as a reference for you to determine the specs that you were used to if you were a 3M stencil user. This chart may be helpful for choosing another stencil, we will keep you updated.

3M Brand Double Liner Stencil

3M’s double liner stencil products for optimum support for the center of letters, numbers and designs patterns. The double liner features a bright yellow, translucent polyester inner liner that enhances the visibility of cut designs during positioning and blasting.

519 series available in a variety of liner types and hole punch styles to meet plotter requirements.

3M Brand Single Liner Stencil

507 is the “butter cut” product for efficient cutting and clean cut lines.

510 is the “letter perfect” product that prevents stretching and design distortion. Offers easy alignment and blast-through.

520 is the “computer cut” product that offers excellent blast resistance as well as preventing stretching and design distortion. Can be used in a variety of application methods including hand-cut, die-cut, flatbed and friction fed operations.

1532 is a versatile product that features very high adhesion. Use this stencil for a variety of sandblasting protection applications including pavers, stone and glass surfaces. Ideal for hand-cut, die-cut, flatbed and friction fed operations.

3M Brand Sandblast Fillers

Fillers are recommended when finer detail work is needed, these coatings helped increase the holding power of the stencil to the stone monument surface during sandblasting operations.

3M™ Sandblast Filler 2 is designed for use on smooth and polished surfaces.

3M™ Sandblast Filler 3 should be used only on axed or frosted surfaces and is the preferred filler for the 3M Sandblast Stencil double liner products (519 Series).

See Technical Data pdfs:

507 Technical Data

510 Technical Data

519 Technical Data 519: die cut, 519S: slot feed, 519T: tractor feed.

520 Technical Data

See 3M stencil chart or view 3M’s flyer page 4:

Apply stencil to a warm, clean and dry surface. When the stencil is applied to cold stone surfaces it is possible for condensation to form as the stone warms. Condensation can affect the performance of the stencil’s rubber adhesive. To minimize shrinkage, allow rubber backing to relax before applying to the stone. Rub down firmly to adhere stencil to the stone.

FOR YOUR REFERENCE ONLY – 3M NO LONGER PRODUCES ANY OF THIS STENCIL.