Ronnie & Brady appear in the Elberton Graniteer this month! Page 12

text follows:

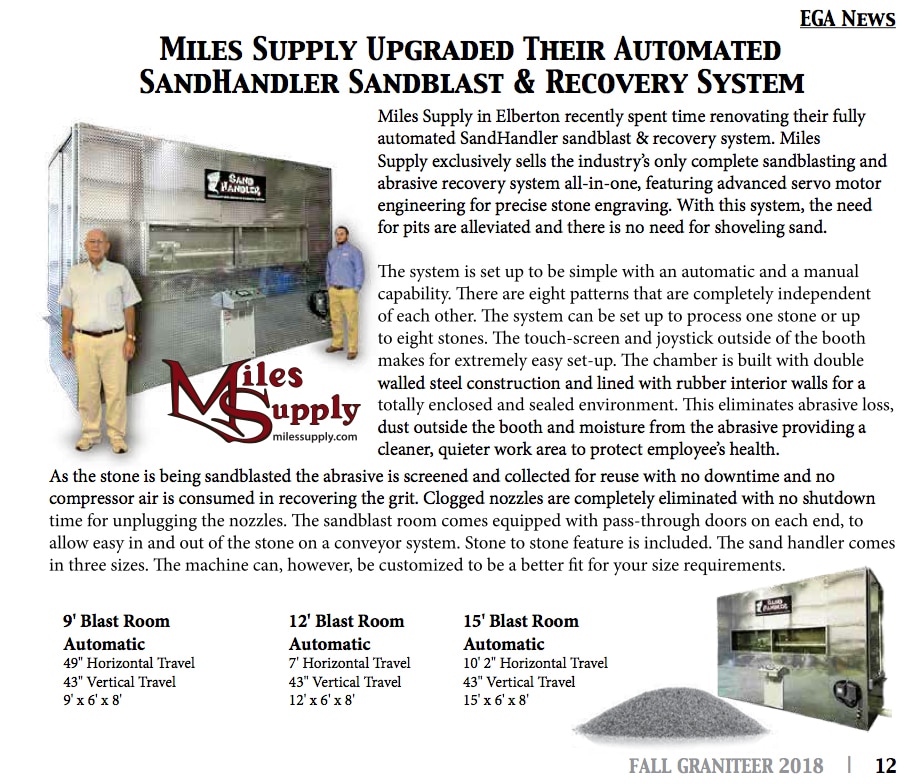

Miles Supply Upgraded their Automated SandHandler Sandblast & Recovery System

Miles Supply in Elberton recently spent time renovating their fully automated SandHandler sandblast & recovery system. Miles Supply exclusively sells the industry’s only complete sandblasting and abrasive recovery system all-in-one, featuring advanced servo motor engineering for precise stone engraving. With this system, the need for pits are alleviated and there is no need for shoveling sand.

The system is set up to be simple with an automatic and a manual capability. There are eight patterns that are completely independent of each other. The system can be set up to process one stone or up to eight stones. The touch-screen and joystick outside of the booth makes for extremely easy set-up. The chamber is built with double walled steel construction and lined with rubber interior walls for a totally enclosed and sealed environment. This eliminates abrasive loss, dust outside the booth and moisture from the abrasive providing a cleaner, quieter work area to protect employee’s health.

As the stone is being sandblasted the abrasive is screened and collected for reuse with no downtime and no compressor air is consumed in recovering the grit. Clogged nozzles are completely eliminated with no shutdown time for unplugging the nozzles. The sandblast room comes equipped with pass-through doors on each end, to allow easy in and out of the stone on a conveyor system. Stone to stone feature is included. The sand handler comes in three standard sizes; but the machine can, however, be customized to be a better fit for your size requirements. And the vertical travel can be customized to 60″. Click to see Request for Quote button.

9′ Blast Room Automatic 9′ x 6′ x 8′

49″ Horizontal Travel | 43″ Vertical Travel

12′ Blast Room Automatic 12′ x 6′ x 8′

7′ Horizontal Travel | 43″ Vertical Travel

15′ Blast Room Automatic 15′ x 6′ x 8′

10′ 2″ Horizontal Travel | 43″ Vertical Travel

Note: because of smoother operation due to the upgraded servo-motors, Sand Handler can be sized smaller and used for other applications such as glass, wood, or metal!

Over 150 sold and running in North America, the SandHandler is established and recognized as a sand blast solution for productivity and satisfying user experience.

While reading the Graniteer Fall issue, we see other members of our staff there (from Elberton events):