Serving Sugar Makers in Washington and Orange counties with CDL maple sugaring products at Miles Supply in Barre, VT

Open weekdays from 6:30–4:30 | (Saturday mornings 8am-12pm only during Maple Season starting in January)

**MAPLE FEVER Event early evening January 16, 2025 4:30 – 7:30pm**

Although we stock popular items, we don’t have everything in this catalog. You may want to call 802-476-3963 to make sure we have what you need, of course we’ll be happy to order it for you and to have it ready for you to pick up! (*prices subject to change)

Pick-up a paper copy at the store. 143 Boynton St Barre VT (across bridge from Spaulding High School)

Open weekdays from 6:30–4:30

143 Boynton St, Barre, VT 05641

Miles Supply, Inc. Barre location is a CDL Sugaring Equipment Corporate Store! The showroom is packed and the warehouse is stocked with sugaring supplies to serve both the hobby producer and major operations in Central Vermont.

Visit Miles Supply in Barre, 143 Boynton St, near Spaulding High School. Call 802-476-3963.

See 2022 CDL maple catalog | See CDL How To Videos

Call 802-476-3963.

CDL Barre

Miles Supply, now also a corporate store “CDL Barre”, is located at 143 Boynton Street in Barre, near Spaulding High School and can be reached at 802.476.3963. Since many of our Barre staff are also sugar-makers, they understand the need for emergency sugaring supplies so they will make themselves available. Call 802-476-3963 during work hours* for this contact information. You can also see it posted on our door. Miles Supply– Building Relationships since 1954!

- *Open weekdays from 6:30–4:30 | Saturday mornings during sugaring season 8–noon.

Here’s an excerpt below, with pictures and edits added, from CDL website.

Hobbyists: Here’s the easiest way to make your own maple syrup!

A few simple ways to successfully make your own maple syrup using a few essential tools you can get at CDL.

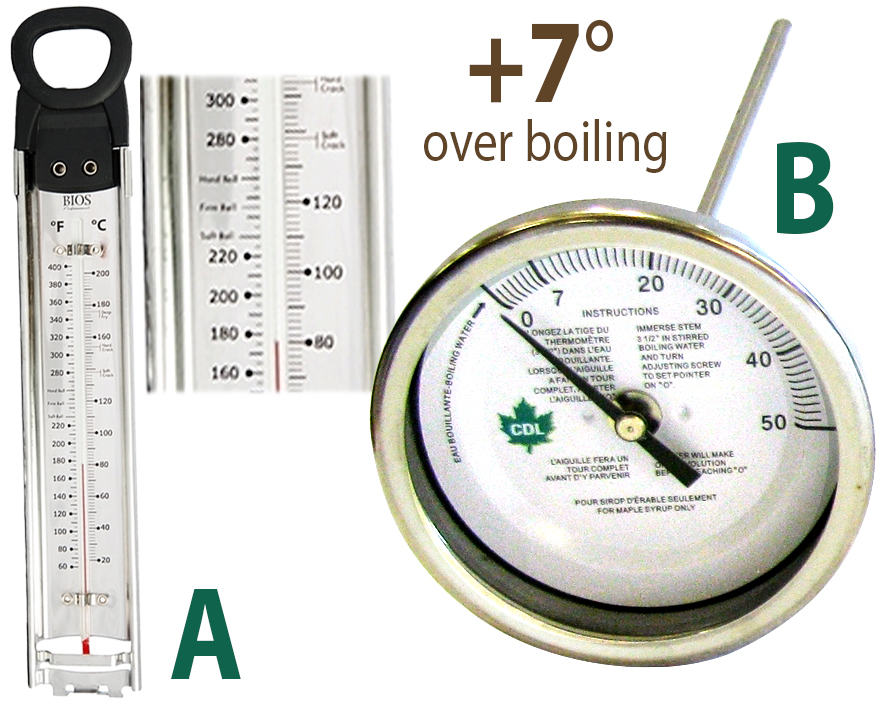

HOW DO YOU CHECK YOUR SYRUP’S PRECISE BOILING TEMPERATURE?

Place the thermometer (A) or stem (B) in boiling water for at least one minute. The water should boil between 211 °F and 213 °F depending on the atmospheric pressure. Let’s say your water boils at 212 °F. With the candy thermometer, your syrup would be ready at 7 °F more, so at 219 °F. With the dial thermometer, when the water boils, you set the needle to zero; when the needle reads 7 °F above the boiling point, the syrup is ready.

HOW DO YOU CHECK THE DENSITY OF YOUR SYRUP?

These are far from the only measuring instruments available! Ask CDL Barre for more information 802-476-3963.

—-

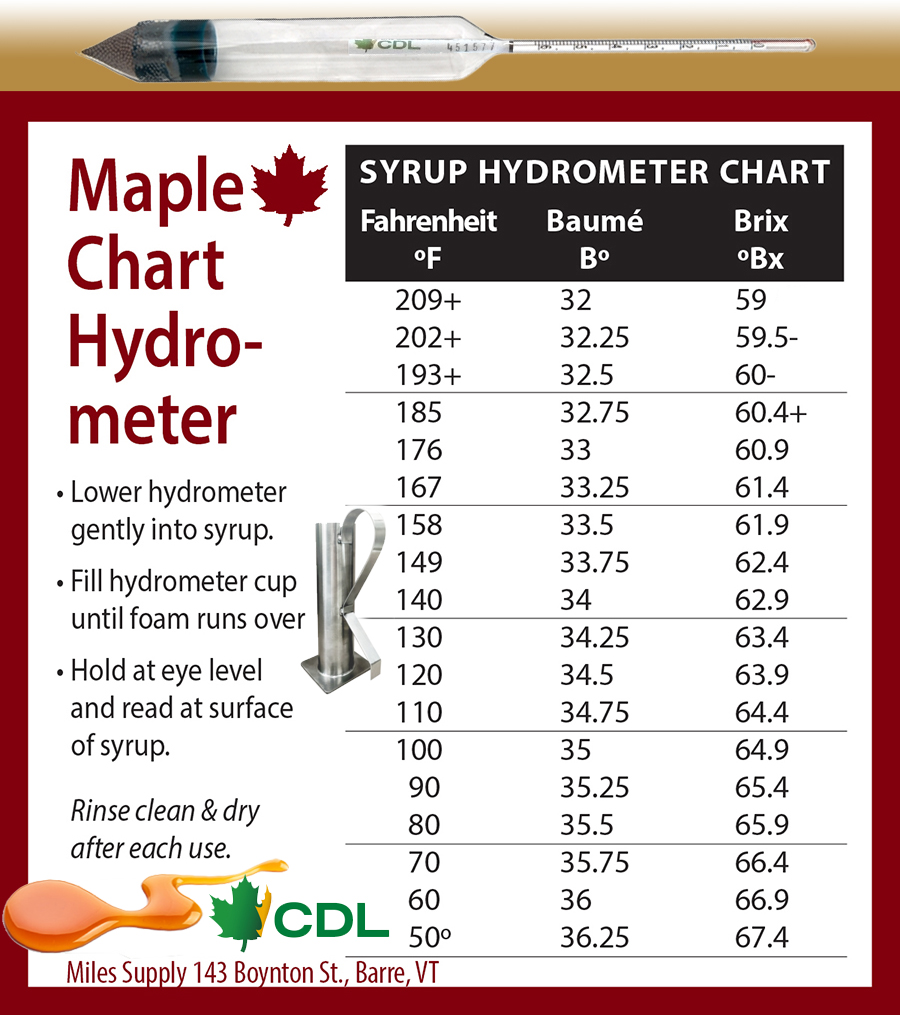

text of the charts above reads:

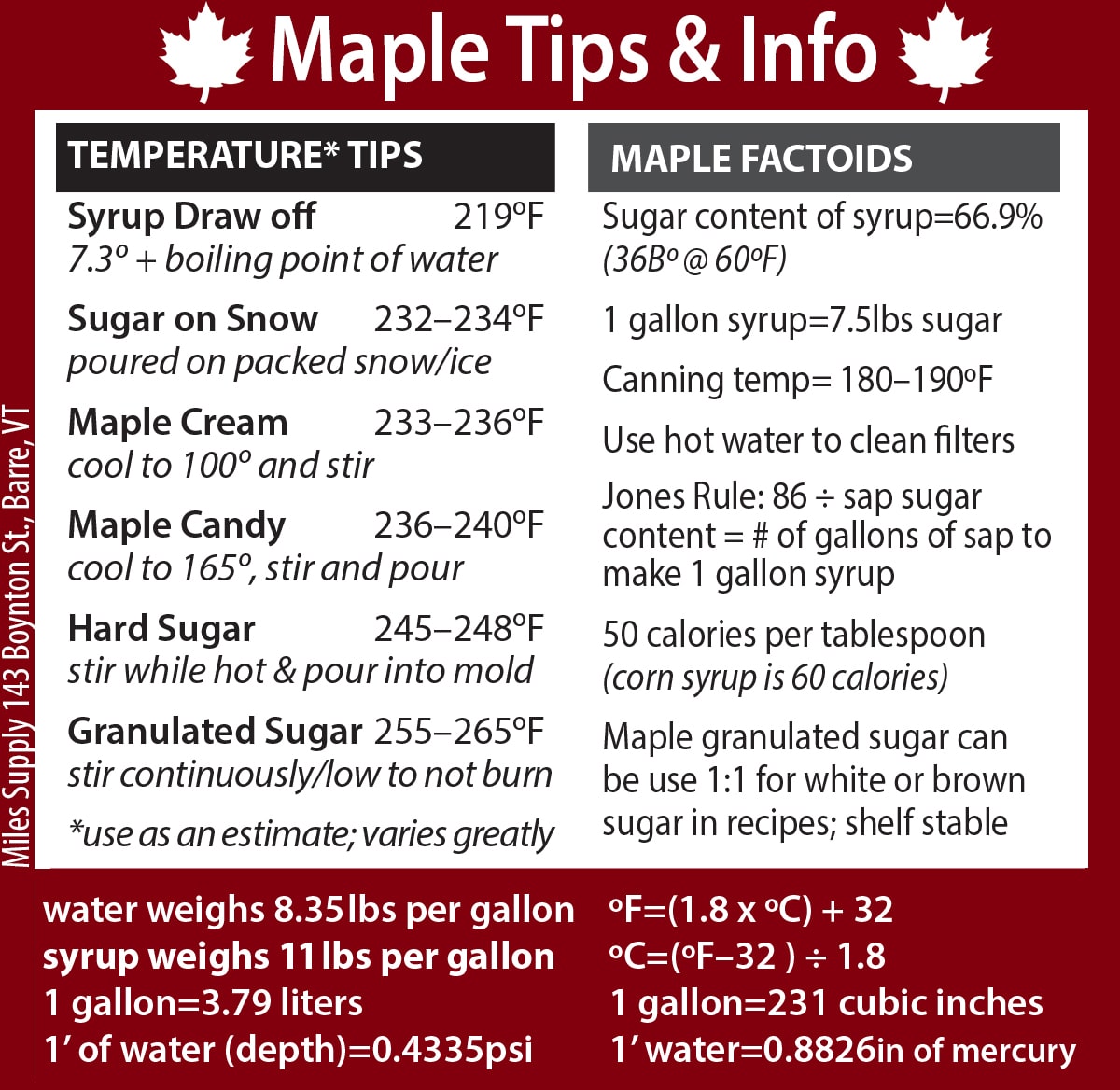

Maple TEMPERATURE* TIPS:

Syrup Draw off 219ºF 7.3º + boiling point of water

Sugar on Snow 232–234ºF poured on packed snow/ice

Maple Cream 233–236ºF cool to 100º and stir

Maple Candy 236–240ºF cool to 165º, stir and pour

Hard Sugar 245–248ºF stir while hot & pour into mold

Granulated Sugar 255–265ºF stir continuously/on low when it’s close because it easily burns

*use as a rough guide; varies greatly

GENERAL MAPLE INFO

Sugar content of syrup = 66.9% (36Bº @ 60ºF)

1 gallon maple syrup = 7.5lbs maple sugar

Canning temp = 180–190ºF

Use only hot water to clean filters

Jones Rule: 86 ÷ sap sugar content = # of gallons of sap to make 1 gallon syrup

50 calories per tablespoon (corn syrup is 60 calories)

Maple granulated sugar can be used 1:1 ratio for white or brown sugar in recipes; is shelf stable

MAPLE CALCULATIONS

water weighs 8.35 lbs per gallon -> syrup weighs 11 lbs per gallon

1 gallon = 3.79 liters | 1 gallon = 231 cubic inches | 7.48 gallons = 1 cubic foot

ºF = (1.8 x ºC) + 32 — note: x “9/5” = 1.8

ºC = (ºF – 32 ) ÷ 1.8 — note: instead of “x 5/9″ like we learned in school, dividing ÷ 1.8 works, too!

water 1 foot deep = 0.8826in of mercury | 1’ deep of water = 0.4335psi

(pick up a print out of this Hydrometer chart & tips at CDL Barre/Miles Supply)

View this Video to browse our stocked & ever changing Showroom – Call 802-476-3963

Now you can get your maple sugaring supplies locally in Central Vermont!

Local maple sugarers are excited to hear that they don’t have to travel so far in order to buy supplies and products they need for their sugarhouse and sugarbush. We know that you don’t wait until it’s time to boil to get your sugarbush and systems in order, come on down to see ways to increase your efficiency and maple production.

Making maple syrup has come a long way from the tap & bucket days. But we have those, too, especially for hobbyists.

We have modern GRAVITY TUBING, MAINLINES AND ELECTROFUSION, TOOLS, WIRES, DRILL BITS AND ACCESSORIES. FITTINGS, VALVES AND PLUMBING, EXTRACTORS, MOISTURE TRAPS AND VACUUM TANKS, VACUUM PUMPS, TANKS AND ACCESSORIES, spouts, buckets, moisture traps, boiling kits.

Also CONCENTRATORS, ULTRAFILTRATION MEMBRANES, EVAPORATORS AND ACCESSORIES (evaporators – wood, chip, pellet, oil).

Reverse osmosis (RO) technology.

MEASURING INSTRUMENT AND EVAPORATOR CLEANING, FILTER PRESSES, BARRELS AND ACCESSORIES.

Don’t forget SIGNAGE, PACKAGING (containers: cans, bottles, jugs, sample jars) and MONITORING.

From PIPELINE to TAPS and ARCHES to RO’s – TAPPING TOOLS, CONTAINERS, FILTERS, and PVC FITTINGS, we have it in-house! Come in and see the latest technology like SPINSEAL and get rid of saddle leaks in your pipeline! Our Miles Supply staff are CDL trained and many of us are also sugar makers – we are prepared to help any size producer.

Maple production supplies in the Washington county area, in Barre!

CDL is known for innovations and expertise in the maple syrup industry.

Whether you’re tapping 50 trees with buckets or 1,000 with tubing, CDL has what you need! The Hobby Zone is for small maple syrup producers but we have modern innovation for any size operation. Equipment and tools customized for maple producers.